Newly distilled whiskey runs into the spirit safe at Buffalo Trace Distillery.

What are Cuts in Whisky Distillation?

How the heads, hearts, and tails are separated

May 27, 2025 –––––– Sam Komlenic

The pot still is the engine that makes so much of our whisky, but pot distillation also creates some undesirable components, and those must be separated from the good stuff. To do that, a distiller makes “cuts” during a production run. The good news is that the unwanted distillate is fairly easily separated, as it arrives at two points—the beginning and the end of a run. The middle part in the sequence is where the quality spirit is made, and accounts for most of the final product. These three stages are known in the U.S. as the heads, hearts, and tails. The Scots know them as foreshots, hearts, and feints.

But how do the three parts get separated? After the distillate passes through the still, it flows from the condenser as distilled spirit. Cuts are separated, and distillers collect them by switching the flow into the appropriate container as the distillate’s character changes along the way.

HEADS

The heads contain volatiles like acetone, and smell like fingernail polish remover or orchard fruit. Methanol is also present, and since it’s poisonous, it must be removed. Heads are oily at first, and that can be felt on the fingertips and seen as cloudiness in the spirit. This is usually discarded, but some distillate near the end of this cut may be saved to blend with the hearts.

HEARTS

Literally the heart of the run, the purest and best-tasting part is typically produced at a still temperature around 185°F to 200°F, compared to roughly 170°F to 176°F for heads and about 208°F for tails. Here you get good, consistently pure alcohol with the aroma and flavor of grain. All of this ends up as whisky.

TAILS

As the run concludes, the temperature rises and tails appear, presenting butanol, acetic acid, furfural, and fusel oils, smelling like a wet dog or sweaty socks. Distillers can monitor temperature and alcohol content with instruments, but they use their senses to determine when to make cuts. Sometimes, tails will be redistilled in the next batch, as they contain recoverable alcohol.

There’s No Cut Clock

There is no defined time to begin and end cuts. Constant monitoring is required, and distillers use a combination of smell, taste, observation, and touch to determine when to make cuts. It also depends on their equipment and the intended age of the whisky. A whisky destined for shorter aging will include less heads and tails, imparting a cleaner flavor. A whisky meant for longer aging usually keeps some of those funky heads and/or tails, which over time in the barrel will transform into rich complexity and better mouthfeel.

Can You Make Cuts After Distillation is Complete?

Some smaller distillers will collect the fractions of an entire run in individual containers, perhaps a dozen or more, then check them all in succession, deciding which should be discarded and which can be blended together for the barrel. This allows them the luxury of making those decisions after the run is complete, without being pressured to choose on the fly.

What About Column Stills?

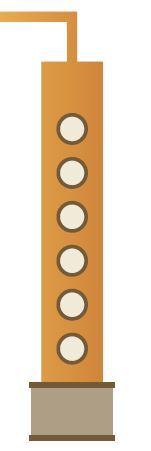

Column stills also create heads, hearts, and tails, but the still separates them automatically. Steam enters at the bottom of the still and rises to meet the downward flow of mash from the top. As the alcohol is stripped away, it rises, and can be removed at any point; the higher the exit point, the higher the alcohol content. Because of this, a column can separate the heads, hearts, and tails automatically and continuously at different points.

![Pairing Whisky With Cigars [Video]](/get/files/image/galleries/260127_WA_Cigars-and-Whisky_Still02-HERO.png?resize=410x0)