Illustrations by Peter and Maria Hoey

Yeast. You hear about it every time someone explains the process of distilling whisky. So where does yeast come from, and how does it carry out its compelling work? Aside from producing alcohol, it has a significant impact on a whisky's flavor. Yeast is far more important than it's given credit for.

What Is Yeast?

Yeast is a naturally occurring single-celled microscopic fungus, and it exists everywhere. There are currently more than 1,500 recognized species. The one that’s most interesting to distillers is Saccharomyces cerevisiae. This variety comprises all brewer’s, baker’s, and distiller’s strains. It produces aromas and flavors in whisky ranging from fruit to spice and flowers to herbs.

How Does Yeast Produce Alcohol?

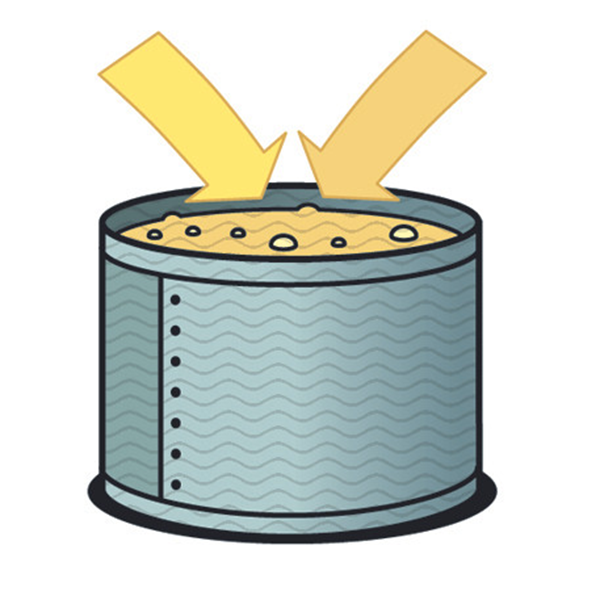

After milling and mashing the grain for whisky production, yeast is “pitched” into the cooled mash to begin the process of fermentation, during which the sugars in the mashed grains get converted into alcohol and CO2. Whisky yeasts generally ferment at warmer temperatures, when they’re more aggressive and can achieve faster and more complete fermentation. During the ferment, yeast produce aldehydes that combine with acids in the mash to form esters, compounds that add various aromas and flavors to the whisky, but they tend to be mostly fruity. Yeast die off after they’ve consumed most or all available sugars, either from the heat of the ferment or from the degree of alcohol that’s been produced. As they die, the esters are released into the mash. The fermented mash is then ready for distilling, which will concentrate the alcohol in the mash into higher-proof spirit ready for the barrel.

How Much Yeast Is Used?

One tablespoon of yeast per 5 gallons of mash, or 2-4 pounds per 1,000 gallons, depending on the yeast strain and distillery practices. The yeast, sensing the feast before them, first go into what’s known as their “exponential growth phase,” budding off enough additional cells to complete the job.

Where Do Distillers Get Yeast?

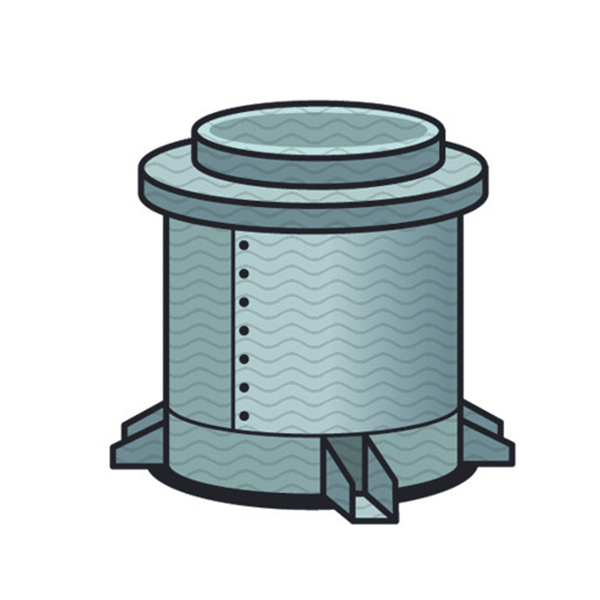

Some distillers propagate their own heritage strains. It’s bred in a larger metal vessel known as a dona tub or can. Often, distillers store their yeast in cryogenic freezers at multiple locations.

Some distillers propagate their own heritage strains. It’s bred in a larger metal vessel known as a dona tub or can. Often, distillers store their yeast in cryogenic freezers at multiple locations.

Others use fresh, commercially produced yeast in every batch. Commercial suppliers have hundreds of strains to choose from.

Others use fresh, commercially produced yeast in every batch. Commercial suppliers have hundreds of strains to choose from.

A third option is to use wild yeast. Traditionally, it’s caught using a crock or jug primed with a “starter” to attract yeast. Typically, it’s made using milled or mashed grain and additional ingredients like hops or sulfur, mixed with water.

A more recent approach is to combine two distinct yeast strains in the mash, called “co-fermenting.” One strain provides better yield while the other adds more flavorful components to the final product.

A more recent approach is to combine two distinct yeast strains in the mash, called “co-fermenting.” One strain provides better yield while the other adds more flavorful components to the final product.