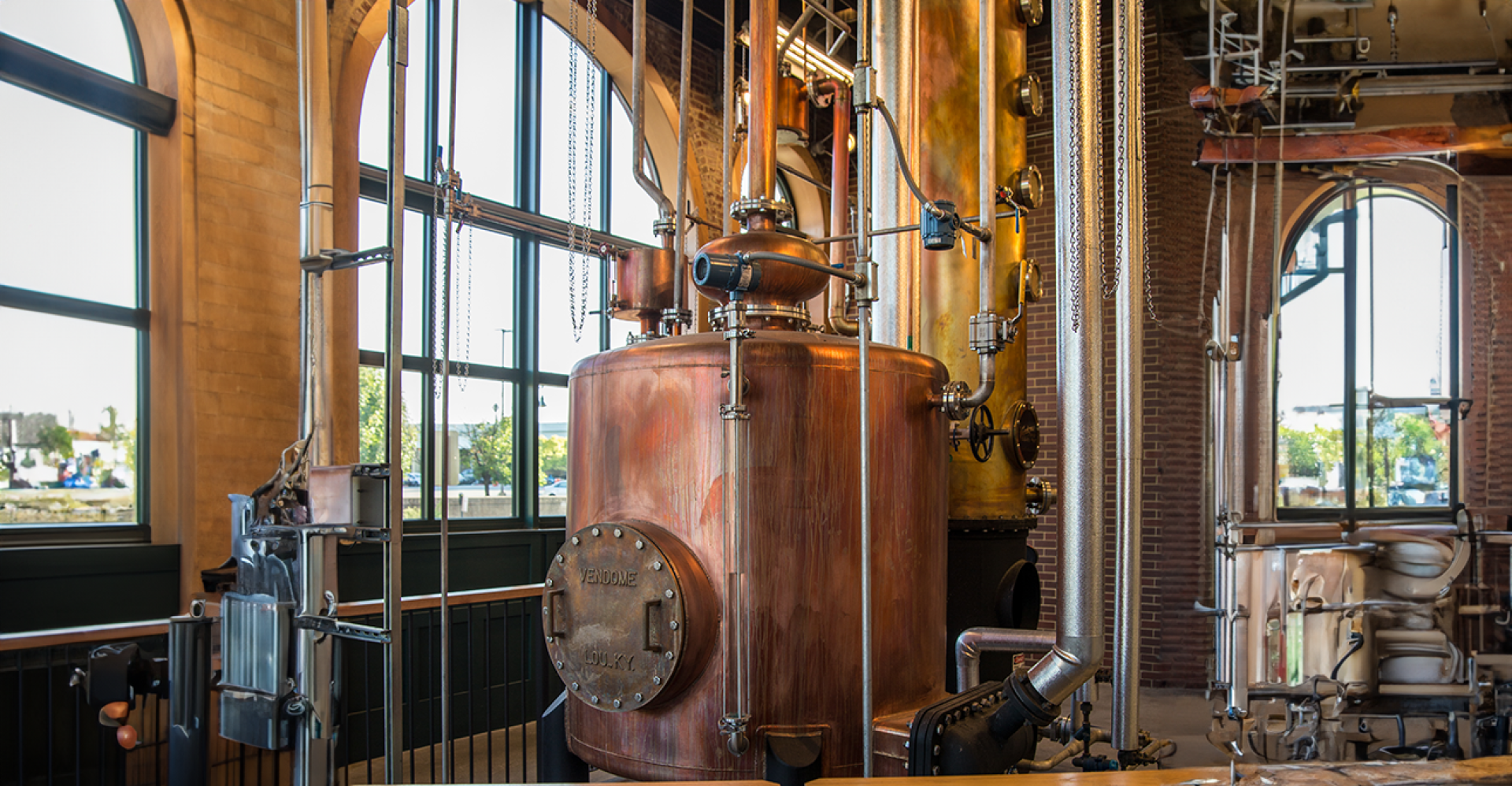

At Angel's Envy, the doubler (foreground, right next to the column still) plays a key role: removing impurities from the distillate while spiking its strength to new heights.

Most whiskies—if not all—have been distilled at least twice. Historically, distillers needed two separate distillations in order to hit target proofs; wash is around 7% ABV, and the first round of distillation in a pot still would only kick it up to around 20%. Double distillation also allows distillers to make an additional round of cuts, removing more imperfections from the distillate. But the process traditionally was tedious and time-consuming, as each batch would need to be collected and re-run through the same still. Advances in technology would eventually streamline the process—specifically, the advent of two new pieces of equipment: the doubler and the thumper. Both are categorized as spirit stills, but they function in different ways.

What Exactly is a Thumper?

A thumper, also known as a thump keg, is a small pot still that sits inside a keg, pre-filled with liquid—typically low wines positioned between the still and condenser. The thumper is connected directly to the lyne arm of the wash still. After the wash is distilled in the first still, the alcohol vapors surge into the thumper, hit the liquid, and begin to condense. The heat from the continued stream of vapor coming off the first still gradually brings the liquid to a boil, launching a cycle in which the alcohol re-vaporizes and achieves a second distillation. That reaction causes a buildup in pressure that creates a loud popping or thumping noise—hence the thumper name. The thumper feeds directly into a condenser, where the vapor is turned into a liquid for a second time before being collected.

A thumper, also known as a thump keg, is a small pot still that sits inside a keg, pre-filled with liquid—typically low wines positioned between the still and condenser. The thumper is connected directly to the lyne arm of the wash still. After the wash is distilled in the first still, the alcohol vapors surge into the thumper, hit the liquid, and begin to condense. The heat from the continued stream of vapor coming off the first still gradually brings the liquid to a boil, launching a cycle in which the alcohol re-vaporizes and achieves a second distillation. That reaction causes a buildup in pressure that creates a loud popping or thumping noise—hence the thumper name. The thumper feeds directly into a condenser, where the vapor is turned into a liquid for a second time before being collected.

What About the Doubler?

Doublers are essentially modified pot stills that, unlike thumpers, accept liquid rather than vapor. Following the first round of distillation, the alcohol vapor travels through a condenser and is cooled into a liquid before it trickles into the doubler. Once the doubler collects a sufficient amount of liquid, it gets heated, typically a steam coil or open fire. That heat brings the low wine to a boil and re-vaporizes it for a second distillation. Those vapors travel into a second condenser, where they are cooled again and then collected.

What are the Advantages of the Doubler?

Modern doublers provide more control over the process; the external heat source allow them to set and hold a particular temperature, which determines both the rate of vapor flow and the end proof. Thump keg reactions are spontaneous by nature and rely on indirect heat, meaning distillers are ultimately at the mercy of the process. While landing on a desired end proof with a thumper isn’t a complete crapshoot, distillers who use them ultimately lack the precision boasted by those who use doublers.

What are the Disadvantages of the Doubler?

Doubler setups require extra equipment. Since doublers take in liquid rather than vapor, distillers need a separate condenser to act as a buffer between them and the wash still. A thumper takes vapor right from the wash still, and so doesn’t require this additional condenser.

Some traditionalists still use thumpers, primarily in the craft spirits scene. Colorado’s 291 Distillery uses thumpers because that’s how founder Michael Myers, a self-taught distiller, first began making whiskey. The thumper is part of 291’s process, which mimics a traditional triple distillation. His mash is first run through a beer still, with the resulting low wine being condensed and transferred to a finishing still, which essentially works as a doubler. The finishing still connects directly to a thumper, which accepts the twice-distilled vapor and carries out the final round of distillation.

So Which is More Widely Used?

Most modern-day distillers have instead opted to use doublers. A typical example is Louisville-based Angel's Envy, which uses column stills for its first round of distillation and a pot still doubler to act as a secondary point of copper contact during distillation, which can help strip undesirable compounds from the whisky. “Due to using a continuous setup…we need a place to remove fusel oils and other low-volatility compounds, since we can’t make cuts like you would on a pot still,” says Angel’s Envy master distiller Owen Martin. He notes that his doubler is operated at a lower temperature than the column still, which decreases the chances of those compounds hanging around past the second distillation. While hitting minimum proof requirements isn’t a concern for Angel’s Envy, which sees its distillate reach 62.5% ABV after its first round of distillation, the doubler does give it a fairly healthy and welcome bump. After passing through its doubler, the distillery’s distillate is proofed at the monstrous 69% ABV, paving the way for high-proof expressions like its annual release Cask Strength Port Finished bourbon.